Aging Test Objectives and Experimental Environment Description

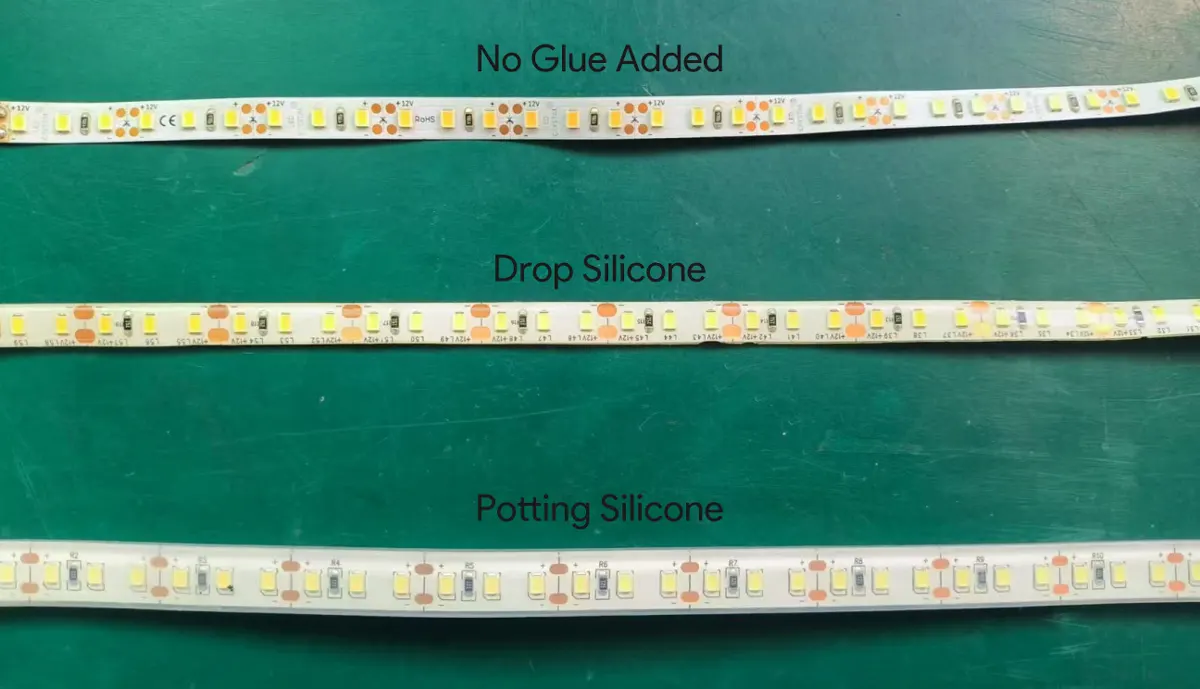

- Test Objective: To evaluate color temperature shifts in LEDs after applying drip-coating or potting resin to commonly used waterproof LED strips across various color temperatures. Record test data and compare color temperature variations before and after applying waterproofing processes (drip-coating vs. potting resin) to provide data support for future LED strip development.

- Tested Products: LED strips are categorized as 1. Non-drop-coated strips, 2. Drop-coated strips, and 3. Potting-coated strips. LED Type: 2835. Supplier: Smalite LED.

- Test Method: Prepare LED strips with different color temperature specifications, standardized at 120 LEDs/meter, DC24V, covering 2400K/3000K/4000K/5000K/6000K color temperatures. Then use an integrating sphere and spectrophotometer to test and record the original data along with color temperature and brightness changes after applying different waterproofing processes.

- Temperature: 28°C ± 5°C

- Humidity: 65% ±5% Test Voltage: DC24V

- Measurement Equipment: Integrating sphere optical testing system / High-precision spectral analyzer

Integrating Sphere Test Data for LEDs with Different Color Temperatures

| Smalite LED Test Data | |||||||||||

| CCT | Power | LED Current | LED Voltage | Luminance | Test Brightness | Voltage | lm/W | CCT(K) | Wave Length(nm) | Ra | Remark |

| 2400K | 0.2W | 60mA | 3.0-3.1V | 22-24lm | 23.26lm | 3.07 | 126.4 | 2406 | 586.1 | 82.5 | SMD2835 |

| 3000K | 0.2W | 60mA | 2.8-2.9V | 28-30lm | 30.04lm | 2.91 | 172.0 | 3032 | 581.7 | 80.92 | SMD2835 |

| 4000K | 0.2W | 60mA | 3.0-3.1V | 24-26lm | 25.74lm | 3.117 | 138.0 | 4065 | 577.6 | 81.4 | SMD2835 |

| 5000K | 0.2W | 60mA | 3.0-3.1V | 25-28lm | 26.74lm | 3.035 | 147.3 | 5162 | 564.2 | 81.3 | SMD2835 |

| 6000K | 0.2W | 60mA | 3.0-3.1V | 26-28lm | 26.35lm | 3.086 | 142.7 | 6533 | 447.7 | 81.9 | SMD2835 |

Comparison Data of Color Temperature Changes in Drop-Coated and Potting-Coated Testing

| Color Temperature Comparison of LED Strips with Drop Glue and Potting-Coated | |||||||||||||

| CCT | LED/m | Voltage | LED Current | Resistance | W/m | LED Power | Flux(Im) | lm/W | Wave Length(nm) | Ra | CCT(K) | Technology | Length |

| 2400K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 626.4 | 101.5 | 586.7 | 83.4 | 2373 | No glue added | 0.5m |

| 2400K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 569.9 | 95 | 582.7 | 87.6 | 2972 | Drop silicone | |

| 2400K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 530.6 | 88.4 | 582.5 | 87.7 | 2977 | Potting silicone | |

| 3000K | 128 | 56Ω | 31mA | 56Ω | 12W | 0.2W | 1998.9 | 166.58 | 582.5 | 82.1 | 3064 | No glue added | 0.5m |

| 3000K | 128 | 56Ω | 31mA | 56Ω | 12W | 0.2W | 1812.9 | 151.07 | 578.6 | 85.6 | 3965 | Drop silicone | |

| 3000K | 128 | 56Ω | 31mA | 56Ω | 12W | 0.2W | 1687.3 | 140.6 | 578.3 | 85.4 | 3974 | Potting silicone | |

| 4000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 662.3 | 110.4 | 577.8 | 82.8 | 4044 | No glue added | 0.5m |

| 4000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 565.6 | 94.2 | 493.4 | 86.5 | 5710 | Drop silicone | |

| 4000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 527.9 | 87.9 | 499.1 | 86.2 | 5669 | Potting silicone | |

| 5000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 700.2 | 116.7 | 569 | 83.2 | 4972 | No glue added | 0.5m |

| 5000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 575.7 | 95.9 | 479.6 | 87.7 | 8287 | Drop silicone | |

| 5000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 535.7 | 89.2 | 480 | 87.5 | 8084 | Potting silicone | |

| 6000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 679.8 | 113.3 | 490.7 | 83.8 | 6344 | No glue added | 0.5m |

| 6000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 525.1 | 87.5 | 474.2 | 87.5 | 19162 | Drop silicone | |

| 6000K | 120 | DC24V | 25mA | 140Ω | 6W | 0.2W | 489.3 | 81.5 | 474.8 | 87.3 | 17861 | Potting silicone | |

Comparison Analysis of Color Temperature and Brightness Across Different LED Strip Encapsulation Processes

After applying three encapsulation processes—adhesive-free bonding, silicone dripping, and silicone potting—to LED strips, significant variations occur in key parameters such as color temperature, brightness (lumens), color rendering index (Ra), and color temperature consistency (CCK). Process selection should be based on application requirements (e.g., prioritizing Ra or CCK).

Color Temperature Variations

As shown in the table below, color temperature changes under different processes are further quantified: Color temperature variations between drip-sealing and potting processes are very similar for 2400K/3000K/4000K, 2400K increased by 600K, 3000K increased by 900K, 4000K increased by 1700K. Significant shifts occur in 5000K and 6000K white light: 5000K increases by approximately 3000-3300K, while 6000K rises by 11500-12900K.

| CCT | No Glue Added | Drop Silicone | Potting Silicone |

| 2400K | 2373 | 2972 | 2977 |

| 3000K | 3064 | 3965 | 3974 |

| 4000K | 4044 | 5710 | 5669 |

| 5000K | 4972 | 8287 | 8084 |

| 6000K | 6344 | 19162 | 17861 |

Luminance Variation

Across processes, luminance in the adhesive-free additive process exceeds that of silicone drip and silicone potting. Drip luminance is about 10%-20% lower than the adhesive-free additive process, while potting luminance is 6%-8% lower than drip.

The brightness of the potting process is about 6%–8% lower than that of the drip process.

Color Rendering Index (Ra)

The Ra of the adhesive-free addition process is generally lower than that of the drip and potting processes, typically by 2%-3%. The color rendering indices of the drip and potting processes are very close, with the drip process being slightly higher than the potting process. This minor difference is essentially negligible.

Conclusion

After applying the three encapsulation processes—glue-free addition, silicone dripping, and silicone potting—to LED strips, key parameters such as color temperature, brightness, color rendering index (Ra), and color temperature consistency exhibit significant variations. During design, it is essential to reference specific parameters to select the appropriate LED chip color temperature and choose different processes based on the application scenario.

Want to learn more about the waterproofing processes used in LED strip lights? Read our blog “What Are The Waterproofing Processes Used In LED Strip Lights?”