Test Purpose

This test report, completed by the Engineering Department, compares LED strip performance before and after glue spraying. It evaluates changes in luminous efficacy and color temperature stability following glue application to provide a technical basis for optimizing process parameters. Simulating real-world application scenarios ensures accurate lighting quality and color rendering.

Measurement Equipment and Environment

- Integrating Sphere Optical Testing System / High-Precision Spectral Analyzer

- Temperature: 28°C ± 5°C

- Humidity: 65% ± 5%

- Test Voltage: DC 12V

- Test Date: July 15, 2024

Test Samples

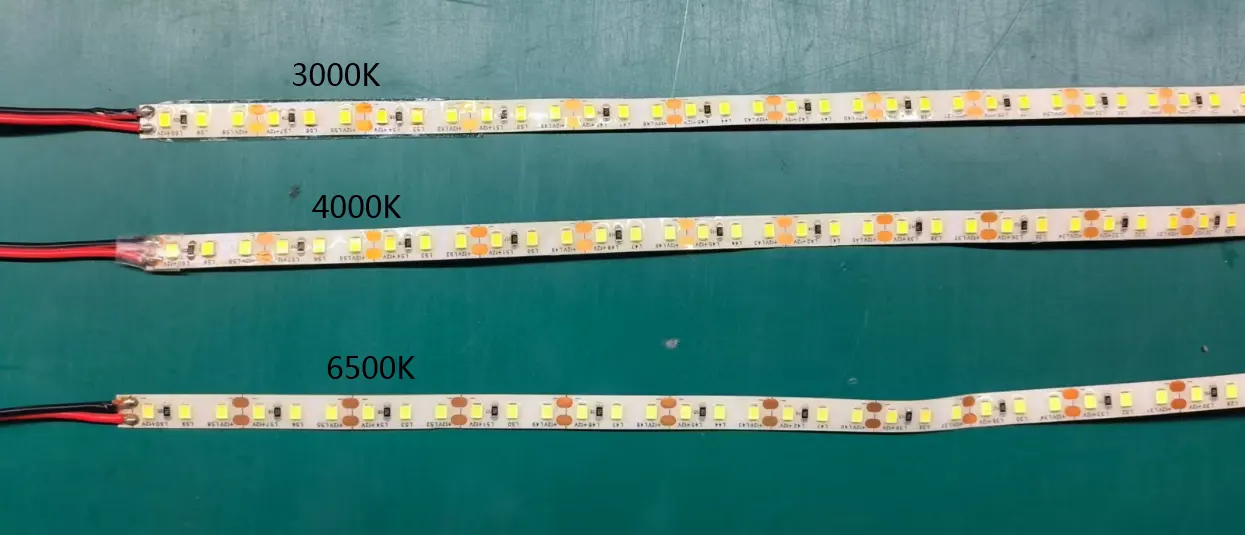

Test samples included one 1-meter length each of standard color temperature LED strips: 3000K, 4000K, and 6500K.

| Item | number of leds | CCT | Product status | Sample length | Number of Samples |

| 1 | 120LED/m | 3000K | No glue added | 1m | 1PCS |

| 2 | 120LED/m | 3000K | Spray silicone | ||

| 3 | 120LED/m | 4000K | No glue added | 1m | 1PCS |

| 4 | 120LED/m | 4000K | Spray silicone | ||

| 5 | 120LED/m | 6500K | No glue added | 1m | 1PCS |

| 6 | 120LED/m | 6500K | Spray silicone |

Testing Method

1) Adjust the DC power supply to output the correct 12V output according to the LED strip’s voltage specifications. Verify the voltage accuracy using a multimeter.

2) Test the light strip before spraying glue using an integrating sphere and spectrophotometer. Record corresponding data, including luminous intensity, luminous efficacy, color rendering index, and color temperature.

3) Test the light strip after spraying glue using an integrating sphere and spectrophotometer. Record corresponding data, including luminous intensity, luminous efficacy, color rendering index, and color temperature.

4) Record and save all data.

Test Data for LED Light Strips Before and After Spraying Glue

| Test Data of LED Light Strips Before and After Glue Spraying | ||||||||||||

| CCT | LED/m | Voltage | LED Current | Resistance | W/m | LED Power | Flux(Im) | lm/W | Ra | CCT | Technology | Length |

| 3000K | 120 | DC12V | 22.5mA | 150Ω | 10.4 | 0.2W | 1139.8 | 107.9 | 81.90 | 2914K | No glue added | 1M |

| 3000K | 120 | DC12V | 22.5mA | 150Ω | 10.78 | 0.2W | 1120.8 | 104 | 82.90 | 3040K | Spray silicone | |

| 4000K | 120 | DC12V | 22.5mA | 150Ω | 10.81 | 0.2W | 1215.1 | 112.5 | 82.70 | 4012K | No glue added | 1M |

| 4000K | 120 | DC12V | 22.5mA | 150Ω | 10.78 | 0.2W | 1185.2 | 109.9 | 83.00 | 4190K | Spray silicone | |

| 6500K | 120 | DC12V | 22mA | 150Ω | 10.5 | 0.2W | 1159.2 | 110.4 | 82.80 | 6632K | No glue added | 1M |

| 6500K | 120 | DC12V | 22mA | 150Ω | 10.56 | 0.2W | 1110.3 | 105.1 | 86.20 | 7076K | Spray silicone | |

Summary Analysis

Luminous Efficiency and Color Temperature Stability

After spray coating, LED strip luminous efficiency generally decreased, while color temperature (CCT) fluctuations increased significantly, particularly noticeable at 3000K and 6500K color temperatures.

Key Parameter Comparison

- 3000K Color Temperature: Luminous efficacy decreased from 107.9 lm/W to 104 lm/W, while color temperature increased from 2914K to 3040K.

- 4000K Color Temperature: Luminous efficacy decreased from 112.5 lm/W to 109.9 lm/W, while color temperature increased from 4012K to 4190K.

- 6500K Color Temperature: After spraying, luminous efficacy decreased from 110.4 lm/W to 105.1 lm/W, while color temperature increased from 6632K to 7076K.

Analysis of Parameter Changes

- Luminous Efficacy Decrease: The sprayed layer (silicone) may have weakened light reflection, increased light loss, and reduced luminous efficacy.

- Color Temperature Shift: The differing absorption/reflection characteristics of silicone material across wavelengths caused enhanced reflection of blue light components at high color temperatures (6500K), shifting the color temperature toward cool white. At low color temperatures (3000K), the silicone’s influence was minimal, resulting in smaller fluctuations.

Process Optimization Recommendations

- Silicone Material Selection: Prioritize silicone with high light transmittance (≥95%) and low color shift to minimize blue light reflection interference.

- Spray Coating Process Control: Achieve uniform application via machine vision motion control systems to prevent luminous efficacy fluctuations caused by uneven thickness.

- Color Temperature Calibration Solution: For color temperatures above 6000K, incorporate trace amounts of red light compensators into the silicone or adjust the blue light proportion in LED chips to stabilize color temperature within 6000K ± 200K. For 3000K-4000K color temperature strips, the silicone spray coating process can be directly applied. For 6500K color temperature, optimize the silicone formulation or add a secondary calibration process to ensure luminous efficacy and color temperature compliance.